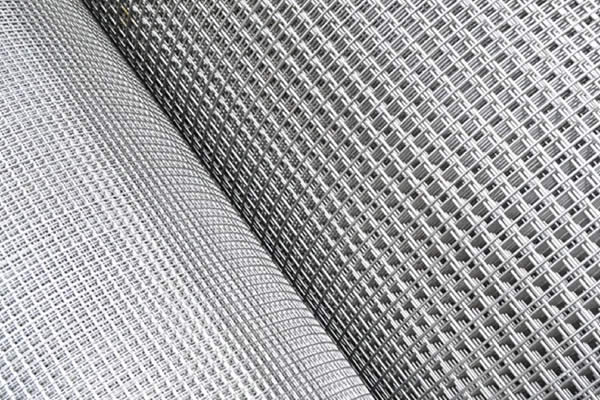

Welded Wire Mesh for Concrete Reinforcement and Security Applications

Dinglian Co., supply Welded Wire Mesh, an assembly of intersecting wires welded at each junction. It offers strength and stability. Common uses include concrete reinforcement, fencing, and safety barriers. Classifications vary by wire gauge (thickness) and mesh size (spacing), influencing its load-bearing capacity and application.

Specifications

- Wire Diameter: Wire diameter, often measured in gauge (e.g., BWG) or inches, determines the mesh's strength; typical ranges span from thin, fine wires (e.g., 24 gauge) to thick, heavy-duty wires (e.g., 0.5 inch) for varied applications.

- Mesh Size (Spacing): Mesh size refers to the clear distance between the wires, usually expressed as the spacing between parallel wires (e.g., 2" x 2", 4" x 4"); it dictates the size of openings and influences the material's function.

- Aperture Shape: Welded wire mesh commonly features square or rectangular apertures, but other shapes like oblong or hexagonal are possible, though less frequent, impacting appearance and suitability for specific uses.

- Width and Length: Standard sheet or roll widths vary, with common sizes including 36 inches, 48 inches, and 60 inches, while roll lengths can range from 50 feet to 100 feet or more, and sheets are typically 8 feet long.

- Material Type: Manufacturers use various materials, including carbon steel (plain or galvanized), stainless steel (e.g., 304, 316), and aluminum, each selected for its strength, corrosion resistance, and intended environmental conditions.

- Welding Method: Resistance welding is the standard process, creating strong, permanent bonds at wire intersections; weld strength is crucial for the mesh's structural integrity and ability to withstand applied loads.

- Surface Finish: Finishes enhance appearance and corrosion protection; options include plain (bare) steel, galvanized (zinc-coated), epoxy powder-coated, or PVC-coated, each offering different levels of resistance to environmental factors.

- Weight per Square Foot: Weight per square foot is an important specification, directly related to wire diameter and mesh size, indicating the amount of material used and influencing the mesh's structural capacity.

- Roll or Sheet Format: Welded wire mesh is available in rolls for continuous coverage or sheets for flat applications; the format affects handling, installation, and suitability for different project scales.

- Edge Treatment: Edge treatment, such as trimmed (cut) or selvedge (original wire end), affects the mesh's appearance, handling, and potential for unraveling, influencing its final application and installation requirements.