Material and Manufacturing Variations in Steel Pipes

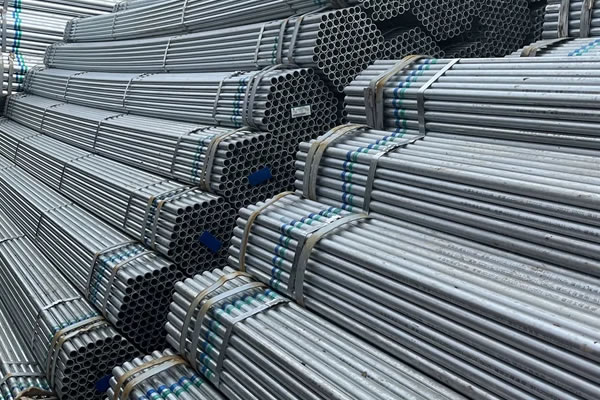

Dinglian Co., supply Steel Pipe. Steel pipes are hollow cylindrical sections, crucial for transporting fluids and gases. Their uses span construction (structural support, scaffolding), infrastructure (pipelines for water, oil, gas), and manufacturing. Classifications vary by manufacturing process (seamless, welded), material (carbon steel, stainless steel, alloy steel), and application (line pipe, structural pipe, casing pipe), each tailored for specific performance requirements and environments.

Specifications

- Nominal Pipe Size (NPS): Ranges from 1/8 to 80 inches, indicating approximate bore size; actual inner diameter varies.

- Outside Diameter (OD): Depends on NPS and schedule; values span from 0.405 to over 86 inches.

- Wall Thickness: Designated by schedule (e.g., SCH 40, 80); thickness influences pressure capacity.

- Length: Standard lengths include 20 and 40 feet; manufacturers also offer custom lengths.

- Material Grade: Includes carbon (A53, A106), stainless (304, 316), alloy steels, each with specific strengths.

- Manufacturing: Methods are seamless (hot/cold-drawn) or welded (ERW, SAW), affecting pipe properties.

- End Finish: Options include plain, threaded (NPT), beveled (for welding), or grooved connections.

- Pressure Rating: Varies with material, dimensions, temperature; determines suitable applications.

- Standards: Complies with ASTM, API, and other standards, ensuring quality and compatibility.

- Coating: May include varnish, galvanization, epoxy, or polyethylene for corrosion protection.