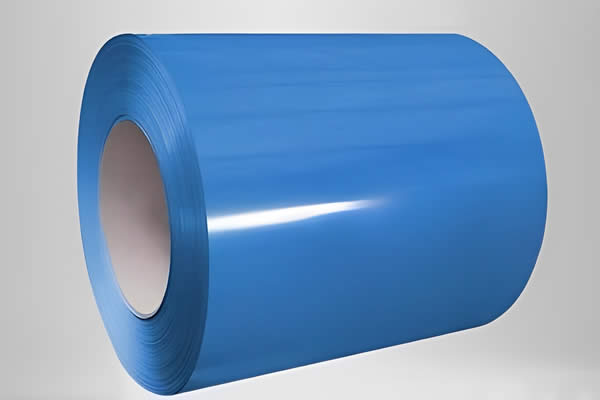

Selecting the Right Aluminum Sheet

Dinglian Co., supply Aluminum Sheet, a versatile material known for its lightweight properties, corrosion resistance, and good strength. Aluminum sheets are widely used across industries, including aerospace, construction (roofing, siding), transportation, packaging, and consumer goods. Classifications are based on the aluminum alloy (e.g., 1100, 3003, 5052, 6061), temper (hardness), and surface finish (e.g., mill finish, anodized, painted), each influencing its specific properties and suitability for different applications.

Specifications

- Alloy: Aluminum sheets are produced in various alloys, including 1100 (high purity), 3003 (good workability), 5052 (high strength), and 6061 (structural), each with distinct properties.

- Temper: Temper indicates hardness, ranging from soft (O) to fully hard (H19), with common designations like H14 (half-hard) and T6 (solution heat-treated and aged) affecting strength.

- Thickness: Aluminum sheet thickness is commonly measured in gauges or inches, ranging from very thin (e.g., 0.006 inches) to thicker sheets (e.g., 0.250 inches), influencing flexibility and strength.

- Width: Standard widths for aluminum sheets often include 36 inches, 48 inches, and 60 inches, providing options for different applications and minimizing material waste during fabrication.

- Length: Common standard lengths for aluminum sheets are 96 inches (8 feet), 120 inches (10 feet), and 144 inches (12 feet), although custom lengths are frequently available.

- Surface Finish: Surface finishes vary, including mill finish (natural), brushed (textured), anodized (enhanced corrosion resistance), and painted, affecting appearance and application suitability.

- Density: Aluminum's density is approximately 2.7 g/cm³ (0.098 lb/in³), a key factor in its lightweight nature, making it desirable for transportation and aerospace applications.

- Tensile Strength: Tensile strength, varying by alloy and temper, typically ranges from 10,000 psi to 70,000 psi, indicating the sheet's resistance to breaking under tension.

- Yield Strength: Yield strength, also dependent on alloy and temper, ranges from 4,000 psi to 60,000 psi, representing the stress at which permanent deformation occurs.

- Thermal Conductivity: Aluminum exhibits high thermal conductivity (around 205 W/mK), making it suitable for heat exchangers and applications requiring efficient heat transfer.