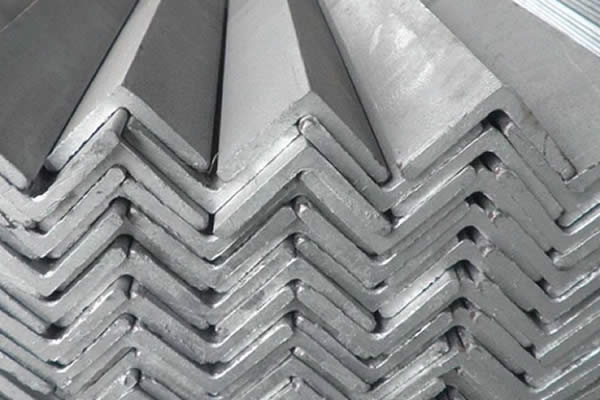

Angle Steel: Strength and Support in Structural Engineering

Dinglian Co., supply Angle Steel, a versatile structural steel shape with an L-shaped cross-section formed at a 90-degree angle. Commonly used for frames, supports, and reinforcements in construction, bridges, and transmission towers. Classifications include equal angles (legs of equal length) and unequal angles (legs of different lengths), as well as hot-rolled and cold-formed variations depending on the manufacturing process and desired strength and finish.

Specifications

- Leg Length: Common leg lengths typically range from 1 inch to 12 inches, offering versatility for various structural needs.

- Leg Thickness: Standard thicknesses generally vary between 1/8 inch and 1 inch, influencing load-bearing capacity.

- Steel Grade: Frequently manufactured using ASTM A36 steel, providing a balance of strength and weldability.

- Manufacturing Process: Hot rolling is the prevalent method, ensuring structural integrity and consistent dimensions.

- Surface Finish: Often available with a mill finish, which can be further processed (e.g., painted, galvanized).

- Weight per Foot: The weight typically ranges from approximately 0.42 lbs/ft to 40.8 lbs/ft, depending on dimensions.

- Standard Lengths: Common stock lengths are usually 20 feet or 40 feet, facilitating ease of handling and application.

- Angle Degrees: Primarily produced with a 90-degree angle between the legs, forming an L-shape.

- Tolerances: Dimensional tolerances adhere to industry standards, ensuring consistency in fabrication and assembly.

- Applications: Widely used in construction, manufacturing, and infrastructure for support and reinforcement.